TO ACCESS MORE DATA YOU NEED TO LOGIN

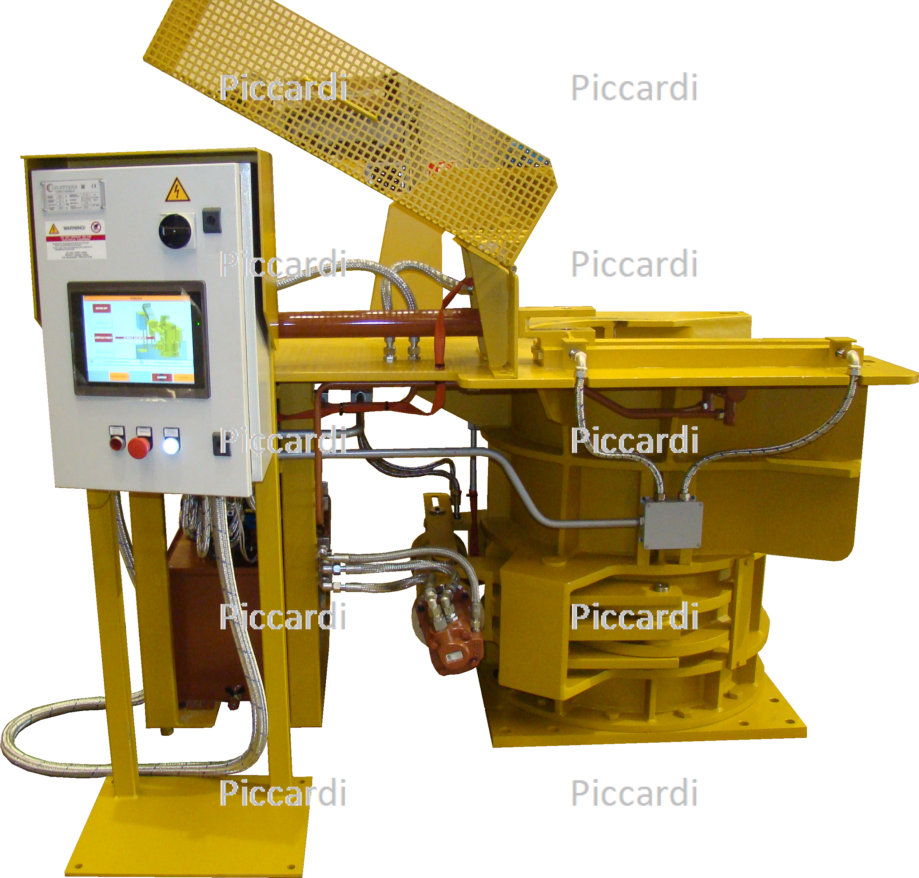

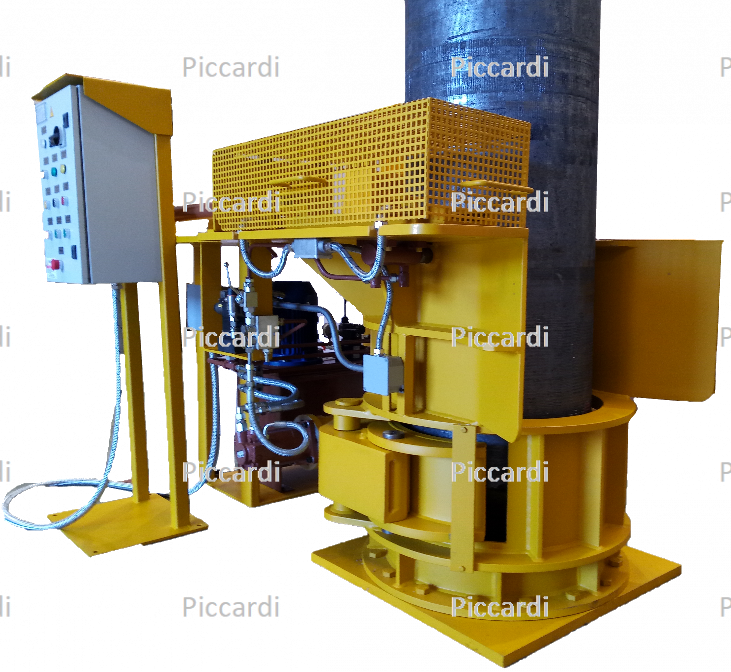

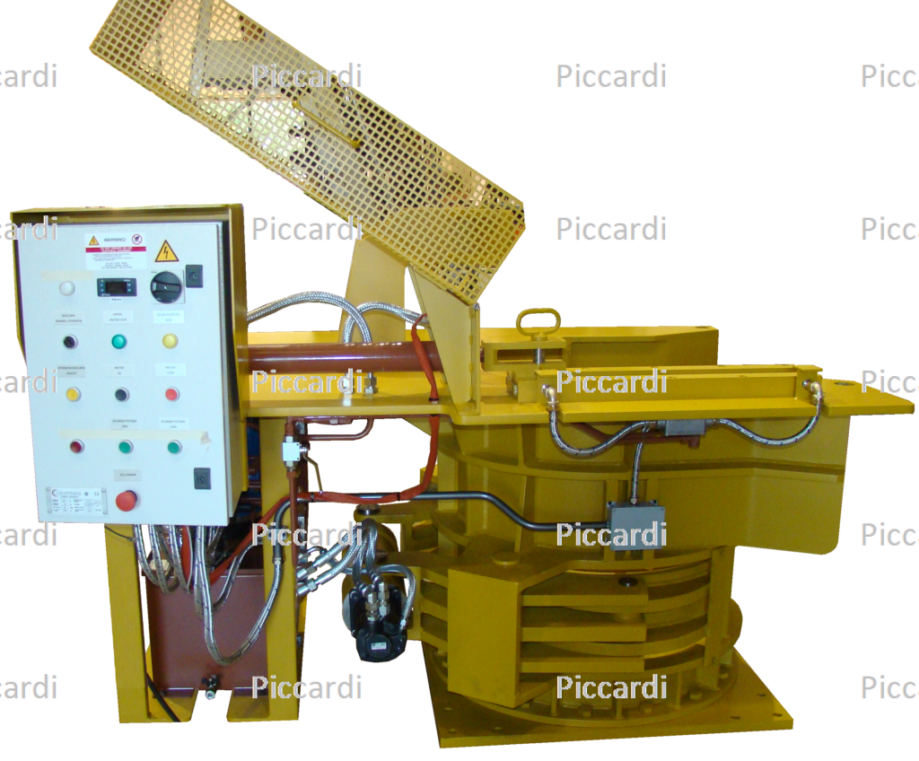

ITEM 26 – Torque station for Graphite Electrodes

An intelligent hydraulic machine for the assembly of graphite electrodes:

- Once the clamps are closed there won’t be any way to open them without willing (oil leakages are not involving the mechanical screw). Clamps can carry the electrode column for long time.

- The U shape give the possibility of approaching very easily sideways with the column and the new electrode

- The lateral opening gives the possibility to take the lifting plugs out very quickly and easily

- Lever clamping collar and cylinder to get a correct assembly and to set the required torque.

- This system allows the unscrewing of previously jointed electrodes.

- The electrode joining operation is driven by a PLC and requires the job of only one person.

- Automatic tightening sequence.

- The display shows the tightening torque that has been reached at the end of the operation.

Standard Version

- Manual distributor for clamps opening and closing

- Tightening push buttons controlled

- Digital display for instant torque monitoring

Gold Version

Provided with the Touch panel:

- controls all the movements of the station, all digital push buttons

- shows all the information about the devices

- shows all the information about the tightening, the last torque reached

- shows diagnostic: alarm messages, input and output states

- remoted electrical board could be far from the electrodes and eventually interlocked with a restricted area